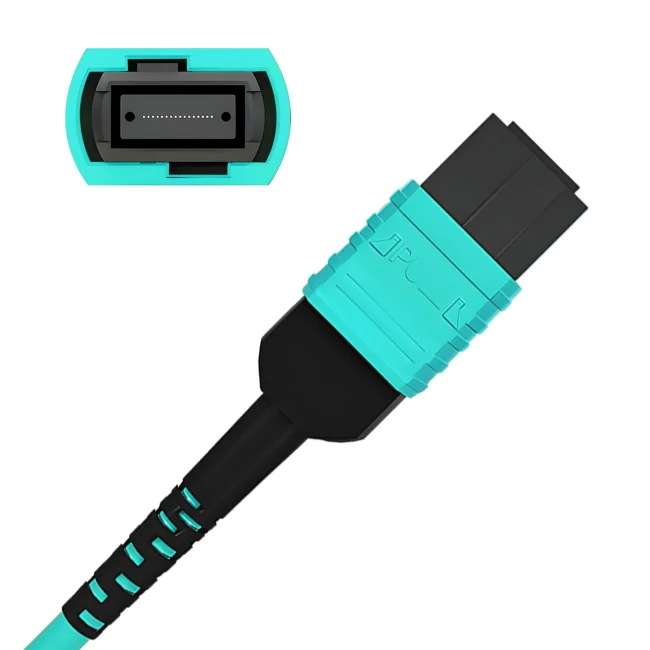

MTP Cable

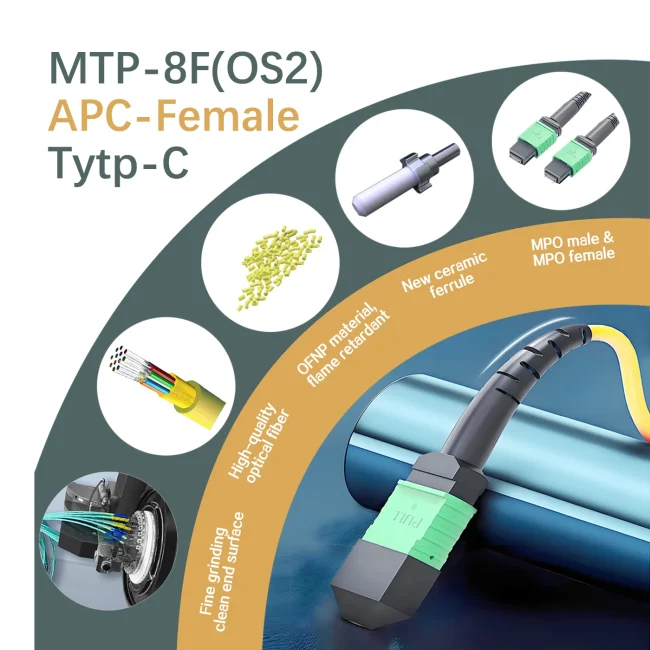

MTP® jumpers provide a smooth upgrade path to higher data rates in data centers when used with our trunk cables. They are commonly applied for patching tasks within equipment cabinets. As a cost-effective alternative to traditional field termination, MTP® cables are optimized for high-density fiber deployments where space savings and simplified cable management are important.

Because MTP®-12 connectors also support MTP®-8 fiber configurations, they are well-suited for 8-fiber parallel single-mode transceiver applications, such as 40G QSFP+ PLR4, 100G QSFP28 PSM4, 400G OSFP DR4/XDR4, and 400G QSFP-DD DR4/XDR4 optical links.

Please note: US Conec’s MTP® connectors are fully compliant with MPO standards and deliver patented mechanical designs, excellent precision, reliable performance, and measurable advantages over standard MPO connectors in demanding environments.

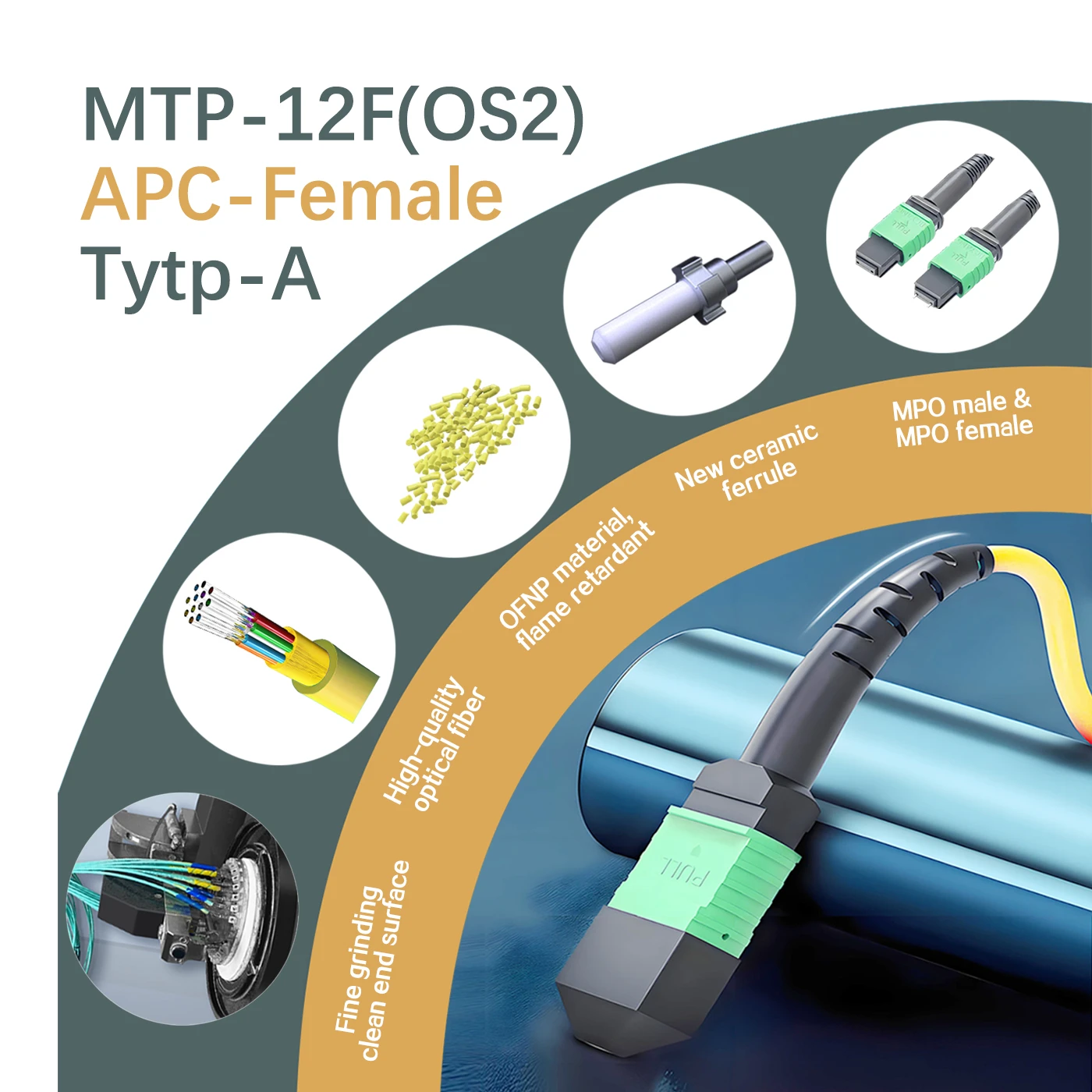

MTP Cable Advantage Specifications

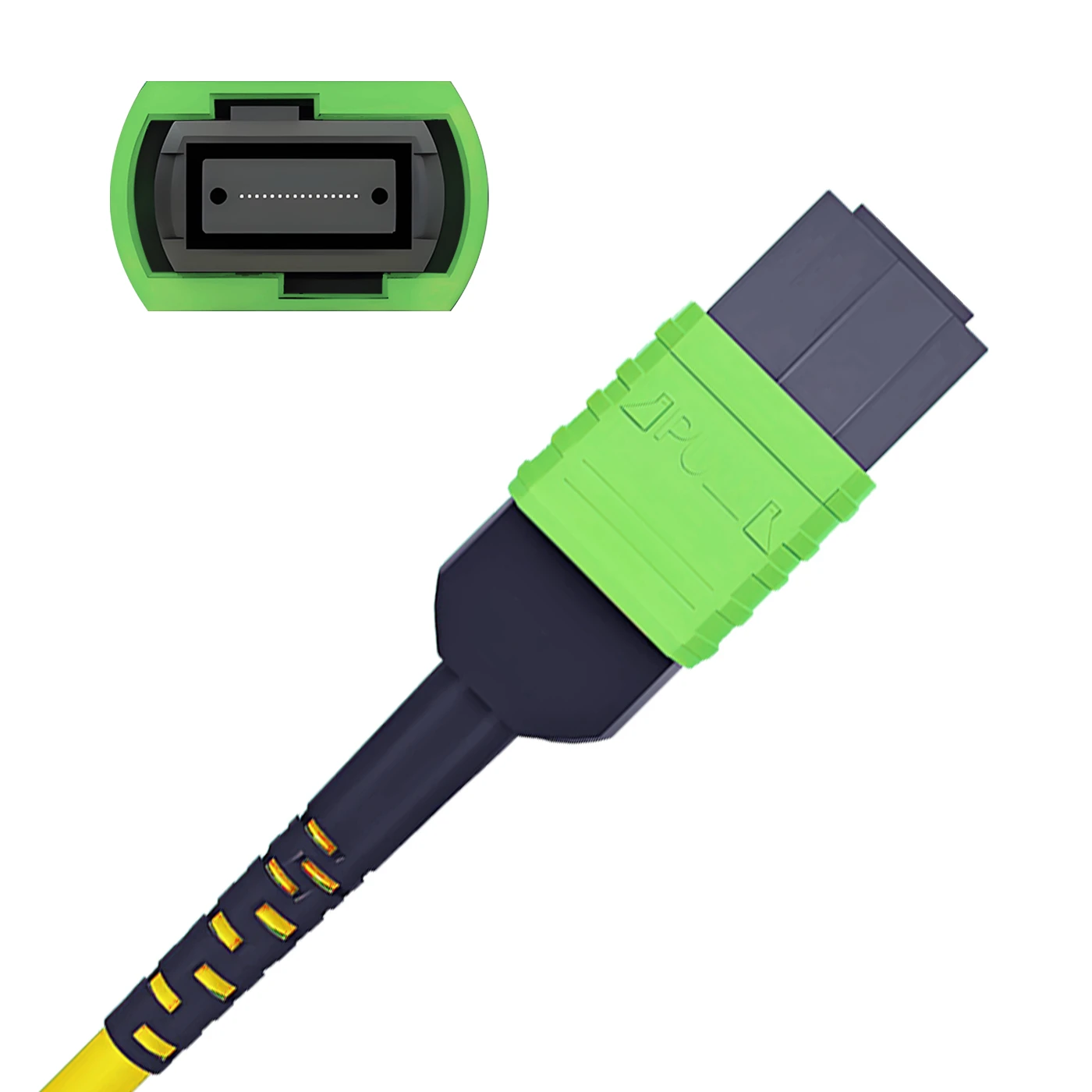

Connector A:US Conec MTP® Elite Female (Pinless)

Connector B:US Conec MTP® Elite Female (Pinless)

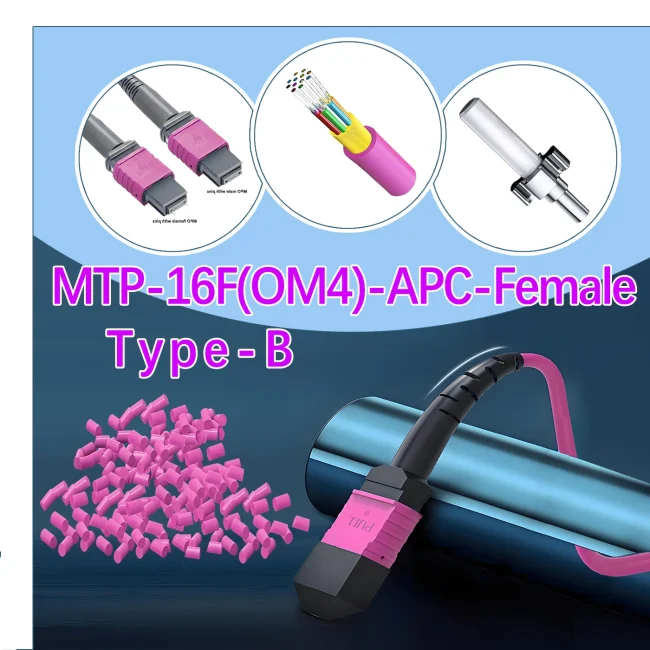

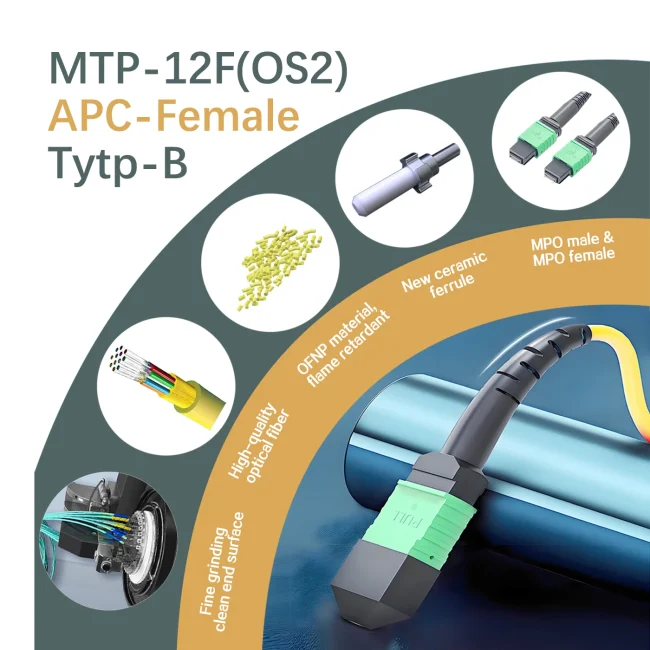

Polish Type:APC to APC

Fiber Mode:OS2 9/125μm(G657A1)

Wavelength:1310/1550nm

Fiber Count:12 Fibers

Polarity:Type A

Cable Outside Diameter (OD):3.0mm

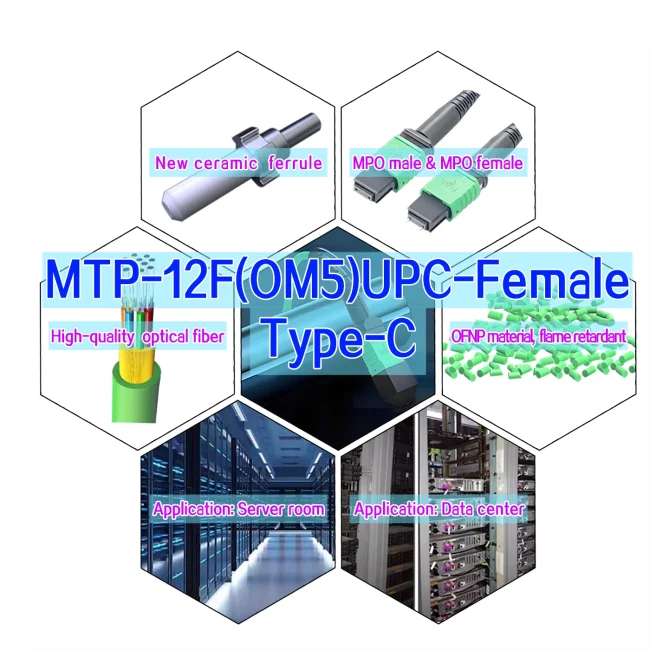

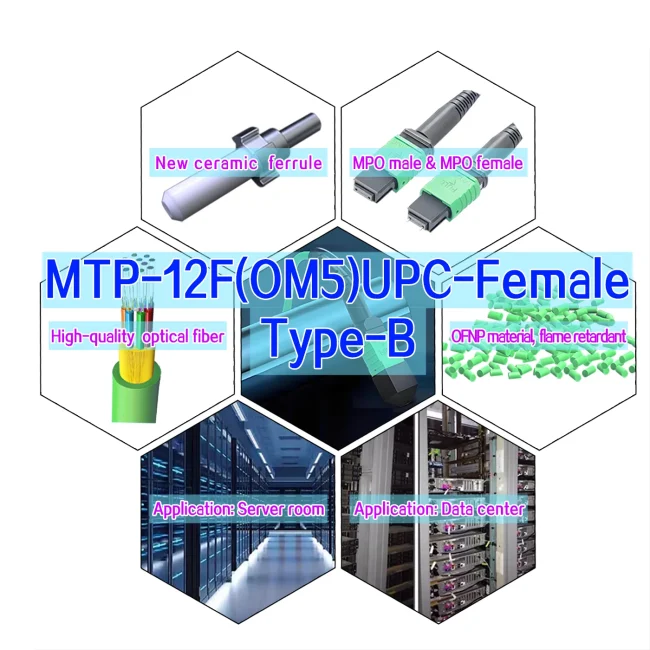

Cable Jacket:Plenum (OFNP)

Min. Bend Radius (Optical Fiber):10mm

Min. Bend Radius (Fiber Cable):10/5D (Dynamic/Static)

Connector Durability:500 times

Tensile Strength:80/240N (Long/Short Term)

Insertion Loss:0.35dB Max (0.15dB Typ.)

Return Loss:≥60dB

Attenuation at 1310nm:≤0.32dB/km

Attenuation at 1550nm:≤0.18dB/km

Operating Temperature:-10 to 60°C (14 to 140℉)

Storage Temperature:-10 to 70°C (14 to 158℉)

*MTP is a registered trademark of US Conec Ltd.

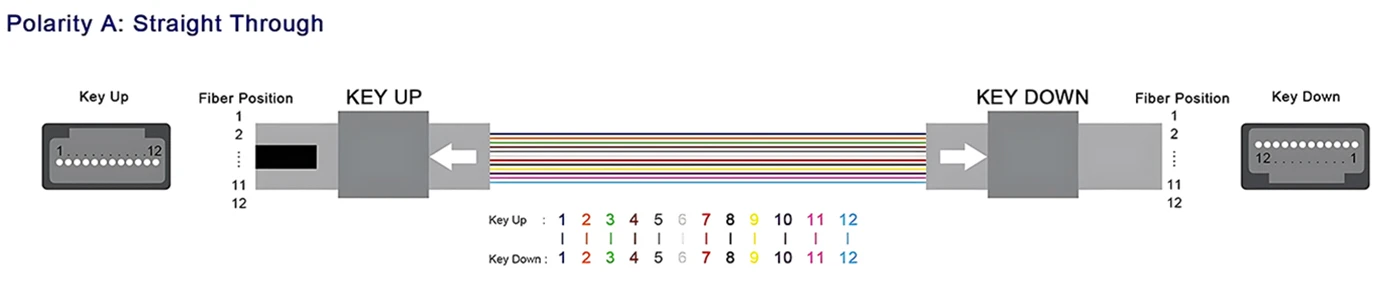

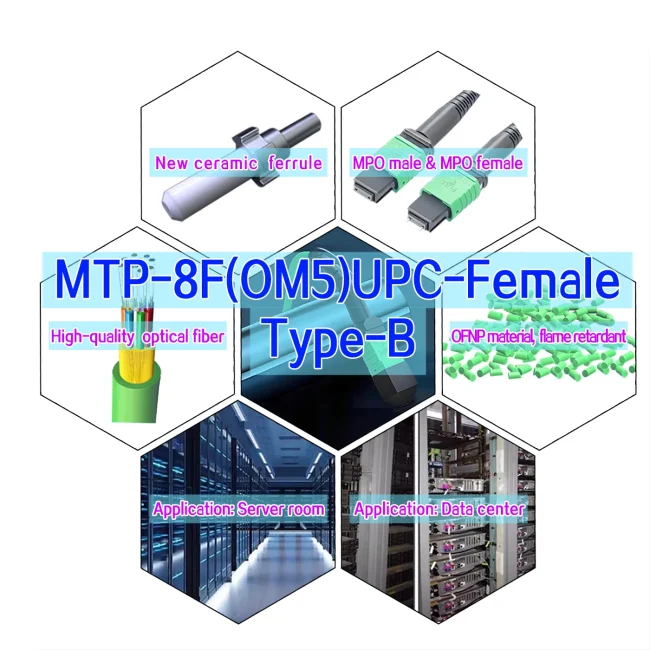

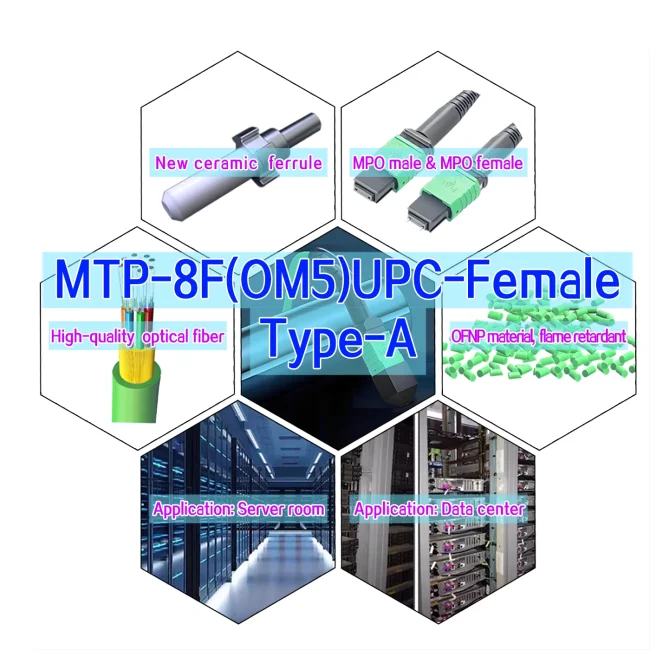

MTP Patch Cable Polarity

The mtp 12 jumper Type A is a widely used fiber optic connector featuring 12 fibers in a straight-line array. It follows a straight-through polarity method, where each fiber connects directly to the same position on the opposite end. Type A is commonly used in structured cabling systems and cassette-based deployments.

mtp 12 jumper Key Features:

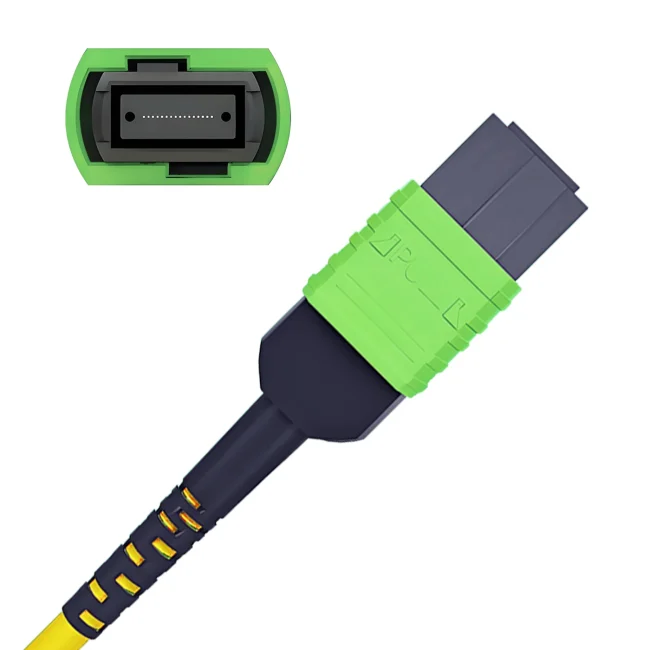

Connector Type:MTP® (Mechanical Transfer Push-On)

Fiber Count:12 fibers in a single row

Polarity Type:Type A (straight-through)

Connector Orientation:Key-up to key-down

Application:10G to 100G Ethernet, backbone cabling, patch panels

MTP Cable Advantage

- 100% use low-loss connectors

- Each MPO patch cord is fully tested for insertion loss & return loss, 100% tested, and batch goods are not sloppy

- Each line guarantees 3D geometric dimensions and end face integrity, imported equipment measures 3D, and dust-free workshops ensure cleanliness

- Affordable price, quality assurance, source manufacturers take both quality and price into consideration

- All materials have passed REACH/ROHS environmental protection requirements and are of export quality

- Adequate inventory, complete materials, and efficient production

- Customization of special specification MPO patch cords, fast delivery

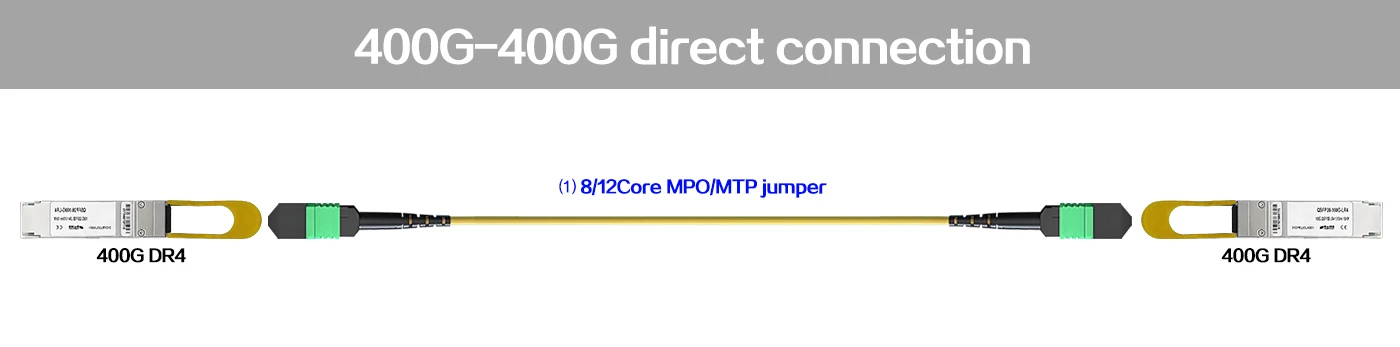

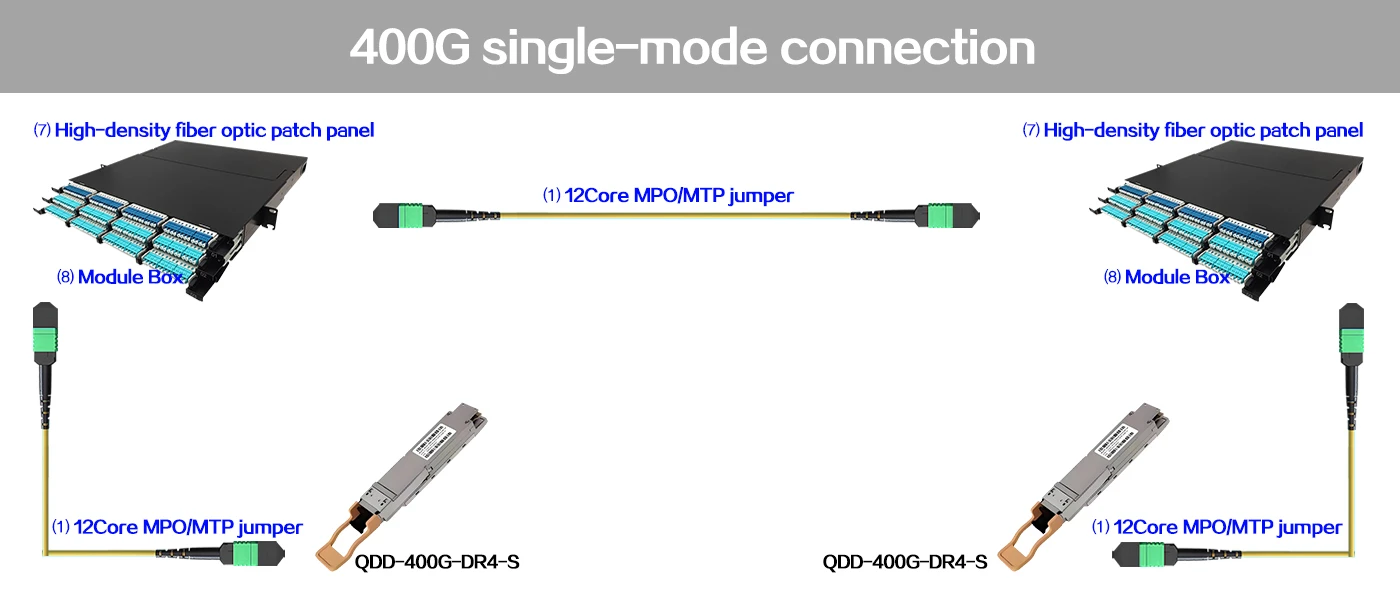

MTP Cable 400G-400G direct connection mode

When the 400G QSFP-DD DR4 optical modules at both ends of the machine room can be connected through MPO/MTP-8 single-mode fiber jumpers to achieve 400G transmission.

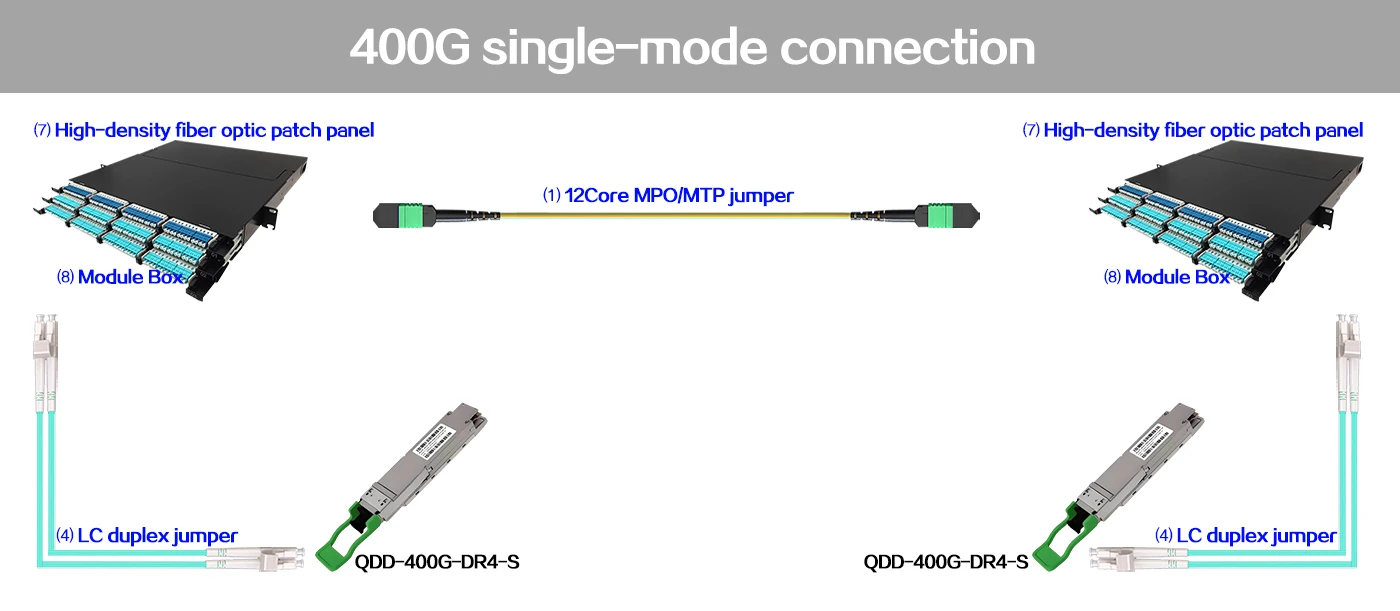

MTP Cable single-mode connection

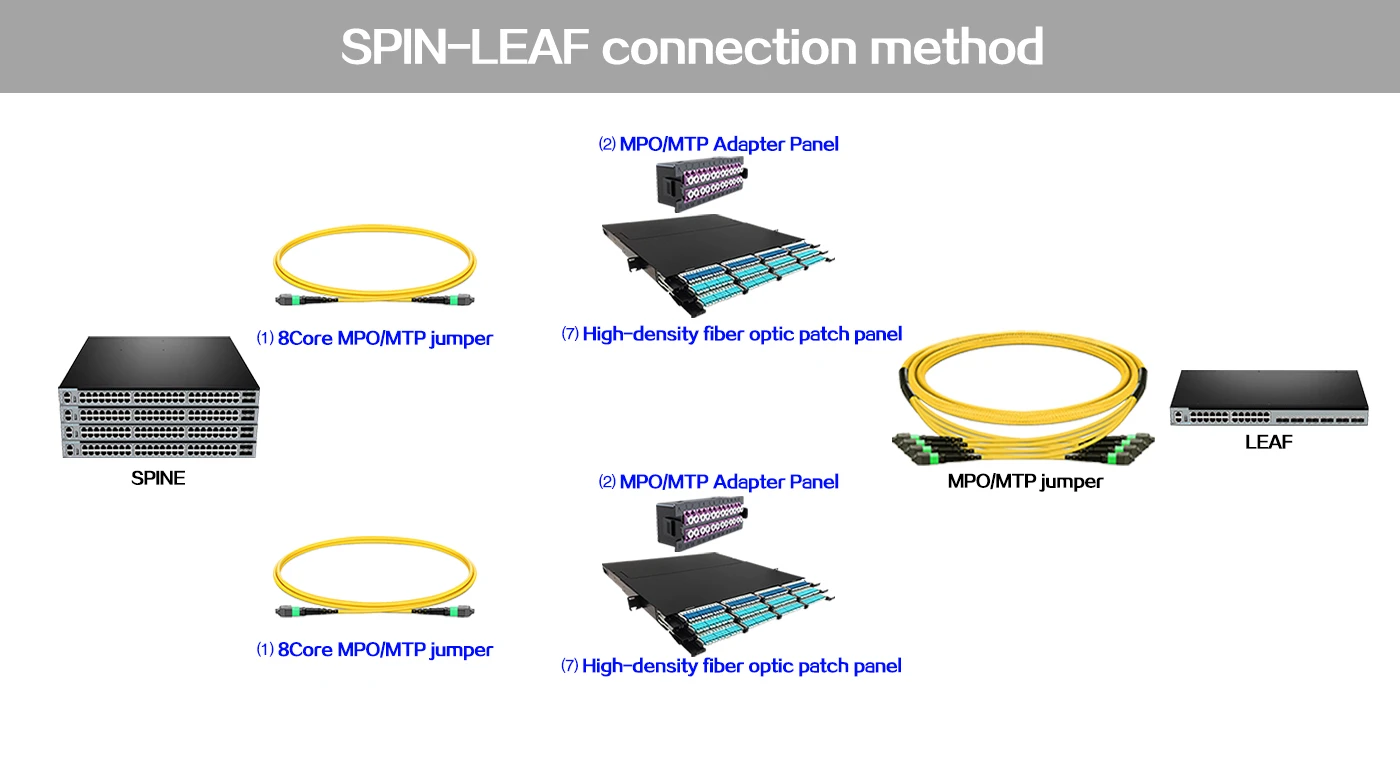

MTP Cable SPIN-LEAF connection method

MTP Cable Application

High-speed interconnection in data centers

It is used for direct connection of 40G/100G optical modules, supports 400G high-speed transmission, and can improve wiring density and transmission efficiency. For example, 400G QSFP-DD DR4 optical modules can be directly connected through MPO/MTP-8 single-mode fiber jumpers.

High-density wiring scenarios

In the backbone wiring of data centers, MTP/MPO trunk fiber jumpers are used in conjunction with adapter modules to achieve interconnection and cross-connection between devices, saving 45% of wiring space. Branch jumpers are used to connect devices with different rates (such as 10G and 40/100G devices).

100G/400G transmission expansion

Supports branch connection of 100G QSFP28 optical modules to 4 25G SFP28 optical modules, or interconnection of 100G CFP optical modules to another CFP.

Fiber-to-Building Applications

It is used for fiber-to-the-building (FTTB) wiring to meet the needs of high-density fiber access.

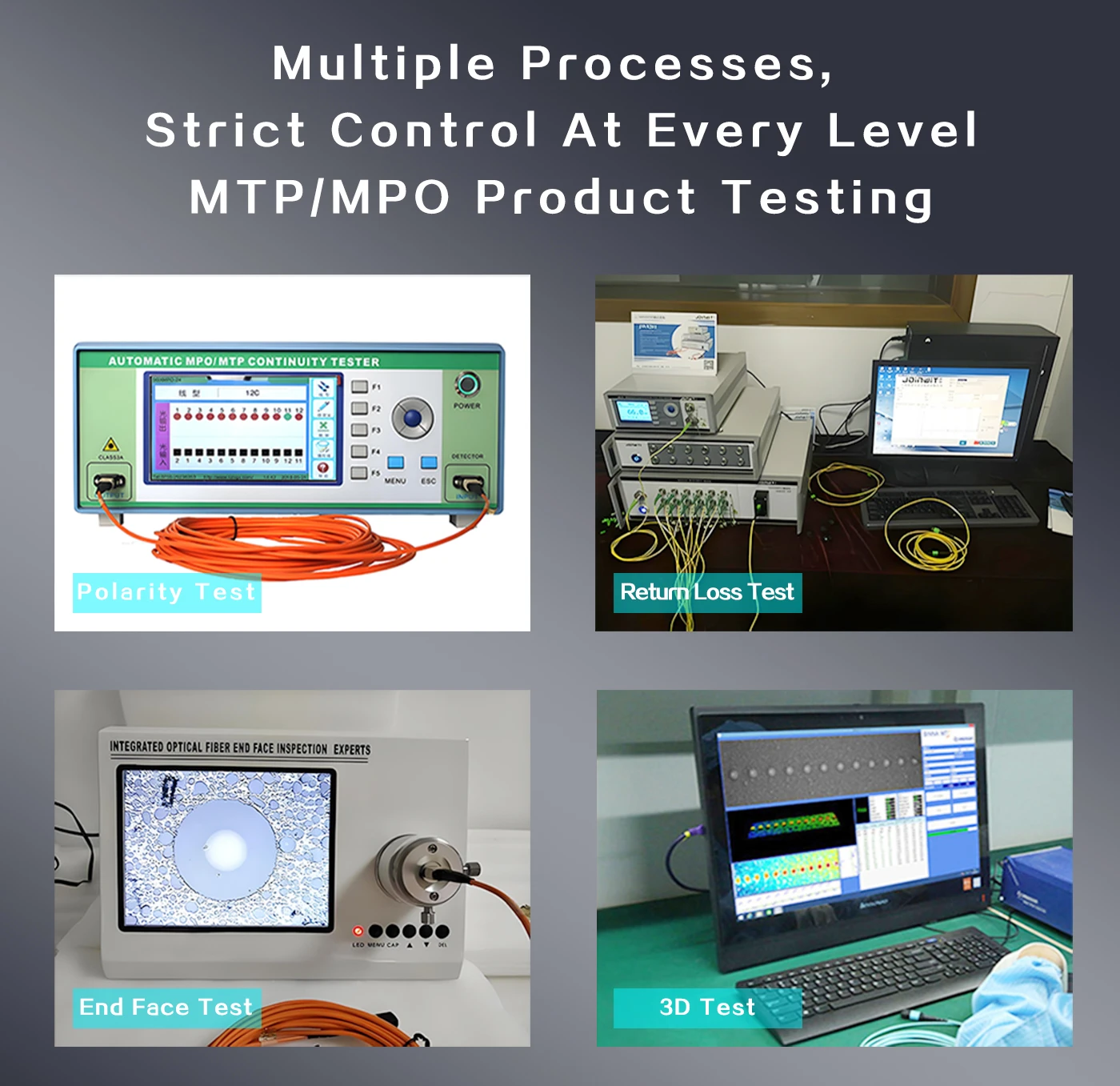

MTP Cable Test Series

MTP Cable Polarity Test Process

End face cleaning: Use special equipment to remove end face contaminants to avoid affecting the test accuracy.

Morphology detection: Analyze the end face microstructure through 3D imaging technology to detect surface roughness, scratches and other defects.

Insertion loss test: Measure the contact loss between the fiber end face and the connector ferrule to evaluate the signal transmission quality.

Polarity verification: Confirm the correspondence between the number of fiber cores and the connector guide hole to prevent communication failure caused by wrong connection.

MTP Cable Test Key Indicators

Cleaning efficiency: It must reach more than 98% to ensure that there are no residual stains on the end face.

Detection accuracy: The resolution of 3D morphology detection must be less than 1.5μ, and the insertion loss error must be controlled within 0.3dB.

Test time: It takes about 10 seconds to detect a single fiber core of a 12-core MPO jumper, and the overall test takes about 2 minutes.

MTP Cable Test Common Problems

Pollution sensitivity: Tiny particles on the end face will cause increased loss, and non-contact cleaning methods are required to protect the end face.

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.