MTP Cable

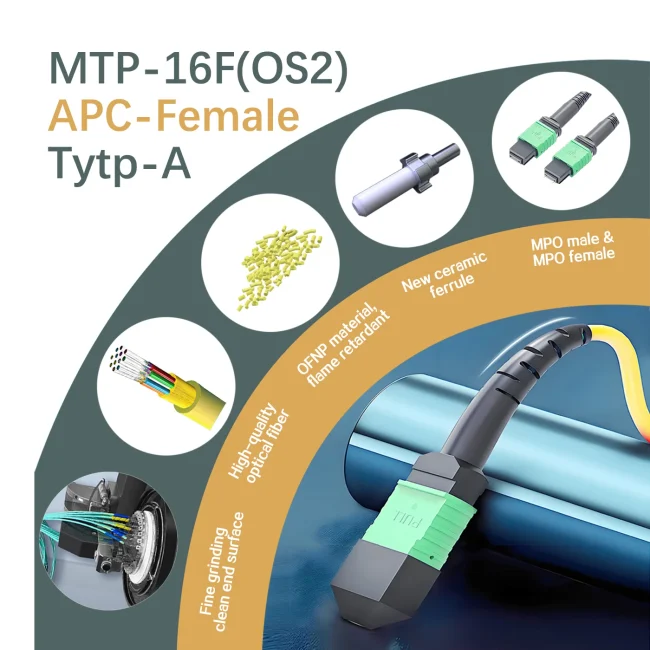

MTP® jumpers support effortless upgrades to higher network speeds in data centers when paired with our trunk assemblies. They are most often applied for interconnections inside a cabinet. MTP® cabling provides a cost-efficient substitute for labor-intensive on-site terminations, engineered for high-density fiber deployments in facilities requiring space optimization and simplified cable handling.

Please note: US Conec MTP® connectors fully meet MPO standard specifications, delivering unique patented innovations, greater accuracy, proven durability, and notable performance gains compared to conventional MPO connectors.

MTP Patch Cable Advantage Specifications

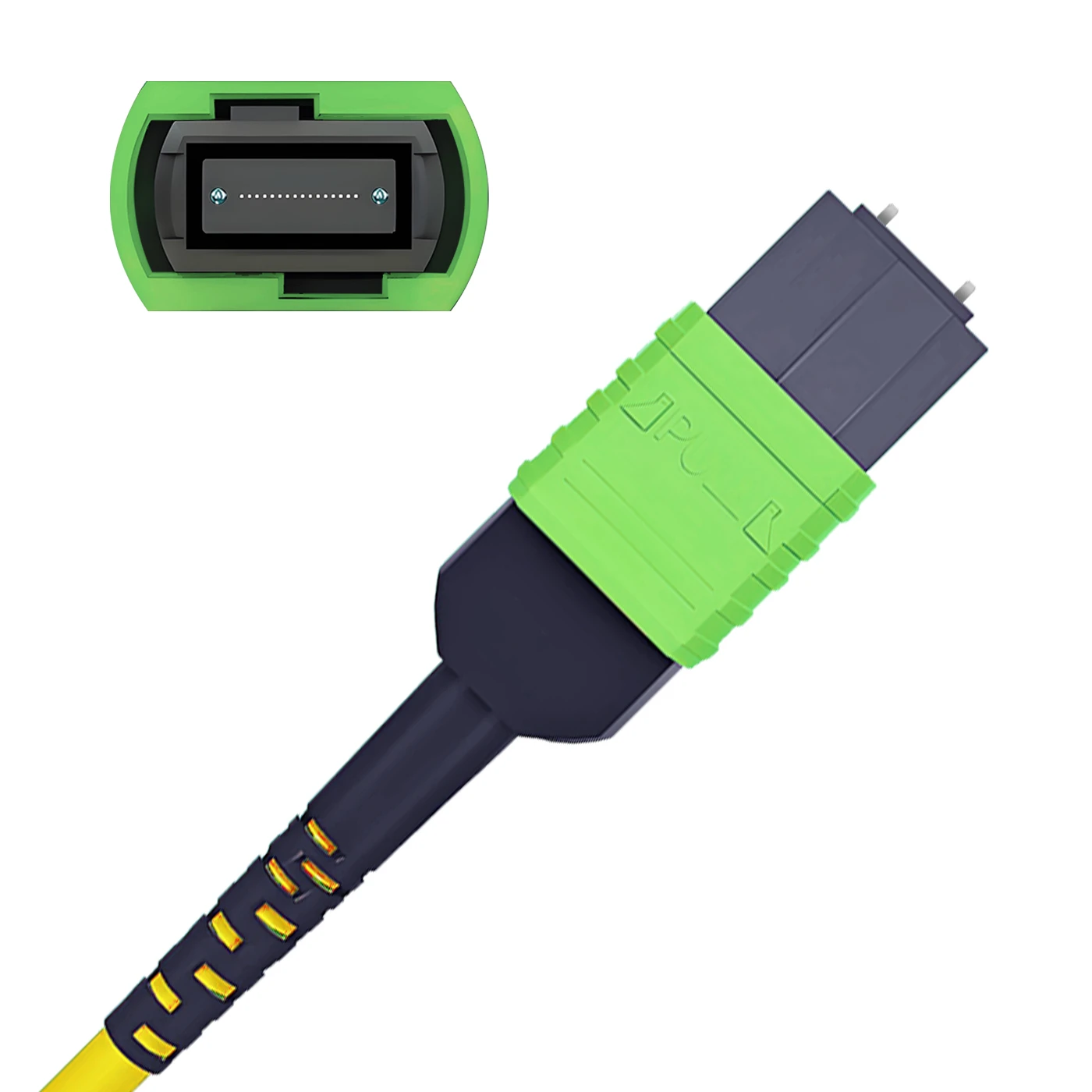

Connector A:US Conec MTP® Elite Male (with guide pins)

Connector B:US Conec MTP® Elite Male (with guide pins)

Polish Type:APC to APC

Fiber Mode:OS2 9/125μm(G657A1)

Wavelength:1310/1550nm

Fiber Count:24 Fibers

Polarity:Type A

Cable Outside Diameter (OD):3.0mm

Cable Jacket:Plenum (OFNP)

Min. Bend Radius (Optical Fiber):10mm

Min. Bend Radius (Fiber Cable):10/5D (Dynamic/Static)

Connector Durability:500 times

Tensile Strength:80/240N (Long/Short Term)

Insertion Loss:0.35dB Max (0.15dB Typ.)

Return Loss:≥60dB

Attenuation at 1310nm:≤0.32dB/km

Attenuation at 1550nm:≤0.18dB/km

Operating Temperature:-10 to 60°C (14 to 140℉)

Storage Temperature:-10 to 70°C (14 to 158℉)

*MTP is a registered trademark of US Conec Ltd.

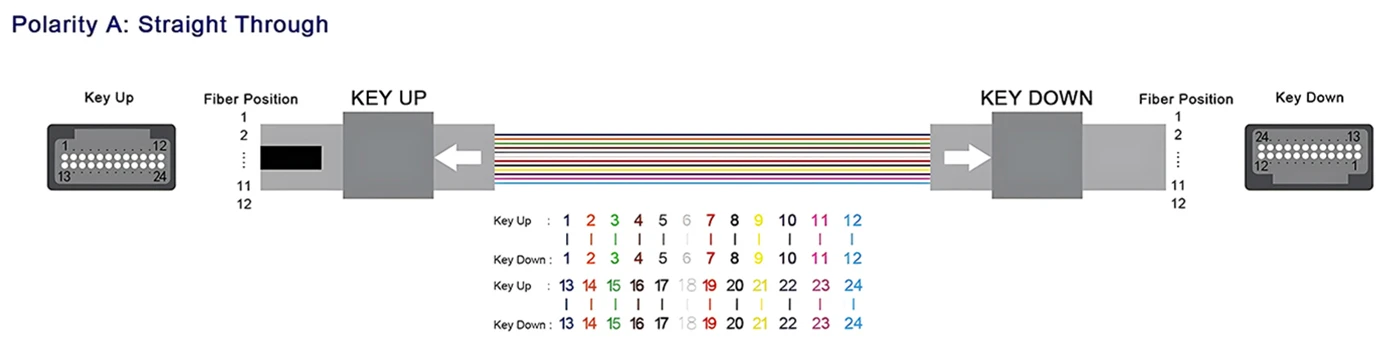

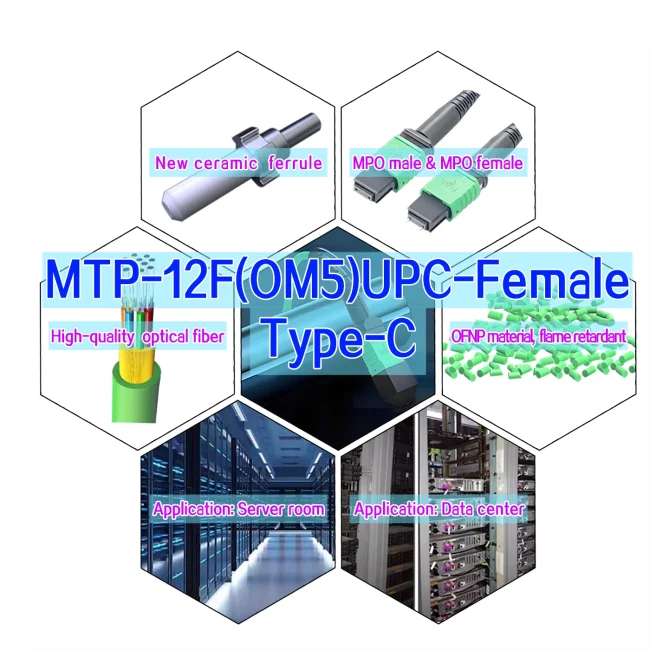

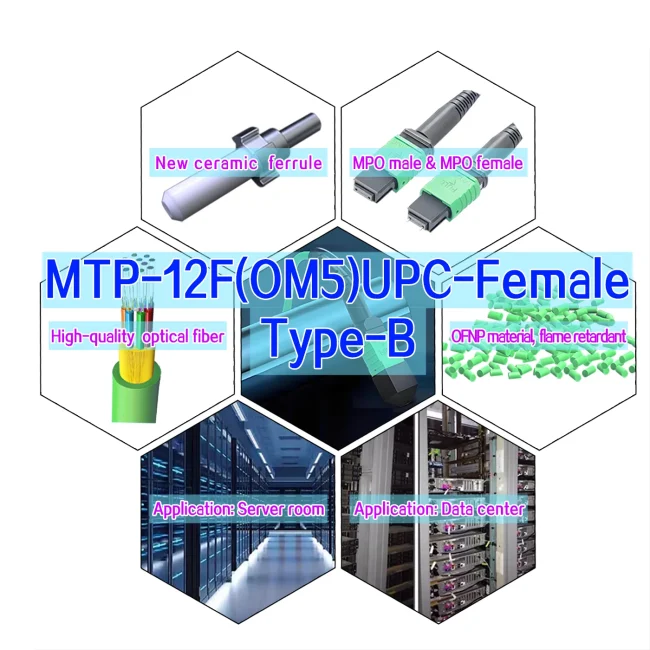

MTP Patch Cable Polarity

The MTP® 24-fiber Type A cable is a high-density fiber optic assembly designed for efficient backbone cabling in data centers. It features a straight-through (one-to-one) polarity configuration, meaning that fiber position 1 at one connector end is directly aligned with fiber position 1 at the other end, and so on through all 24 fibers.

mtp 24 jumper Key Features:

Structure and Components

Connector type: MTP® (US Conec compliant), 24-fiber version

Fiber count: 24 optical fibers arranged in a single high-density ferrule

Polarity: Type A (straight-through)

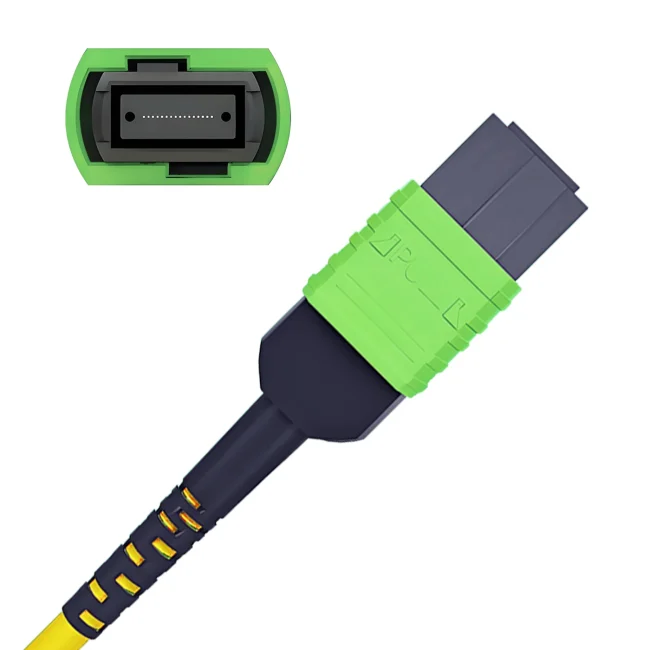

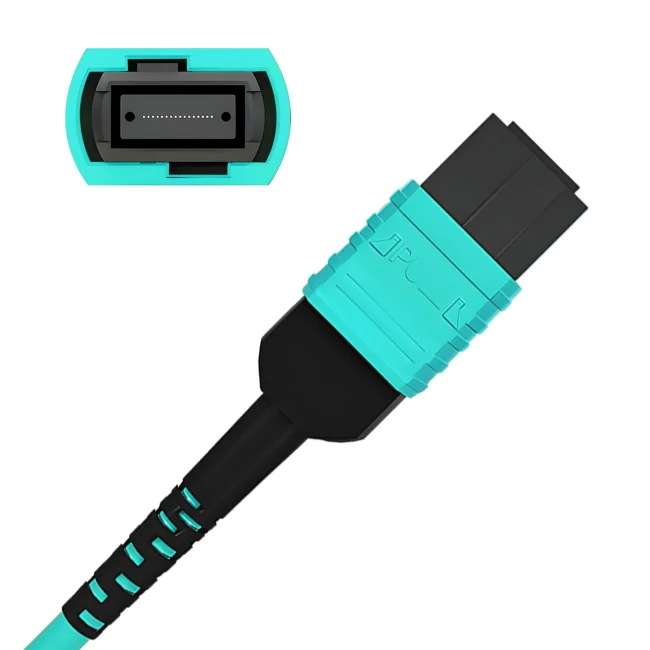

Cable jacket: Usually available in OFNR, OFNP, or LSZH ratings, color-coded by fiber type (e.g., aqua for OM3/OM4, yellow for OS2)

Application

Backbone cabling: Used to connect high-density trunk cables between distribution frames, patch panels, or MTP® cassettes

Data center environments: Supports parallel optics and high-speed applications, such as 100G, 200G, and 400G Ethernet

Migration-ready: Compatible with structured cabling systems for easy transition to higher data rates without major re-cabling

Key Advantages

High density: 24 fibers in a single connector reduce the number of cables needed

Fast deployment: Factory-terminated and tested for low loss and quick installation

Polarity simplicity: Type A provides straightforward fiber mapping, making it easy to manage in certain structured cabling designs

MTP Cable Advantage

- 100% use low-loss connectors

- Each MPO patch cord is fully tested for insertion loss & return loss, 100% tested, and batch goods are not sloppy

- Each line guarantees 3D geometric dimensions and end face integrity, imported equipment measures 3D, and dust-free workshops ensure cleanliness

- Affordable price, quality assurance, source manufacturers take both quality and price into consideration

- All materials have passed REACH/ROHS environmental protection requirements and are of export quality

- Adequate inventory, complete materials, and efficient production

- Customization of special specification MPO patch cords, fast delivery

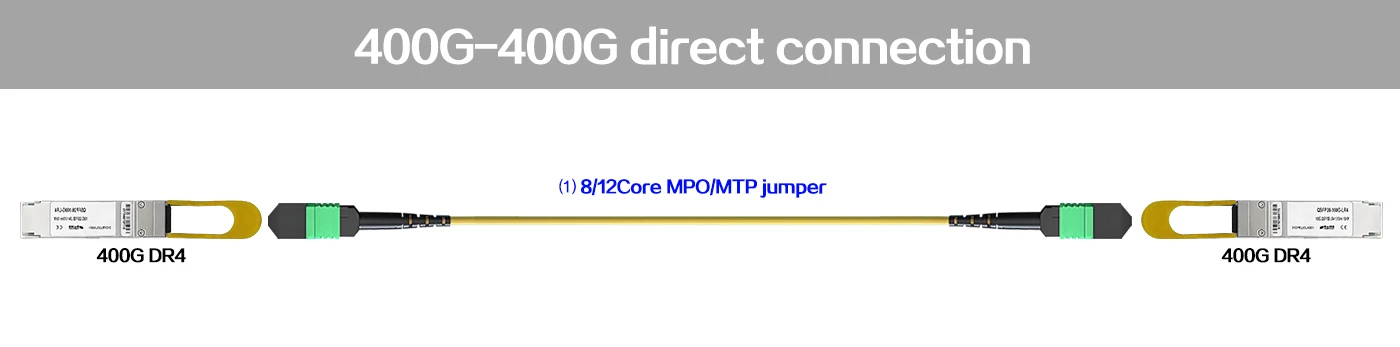

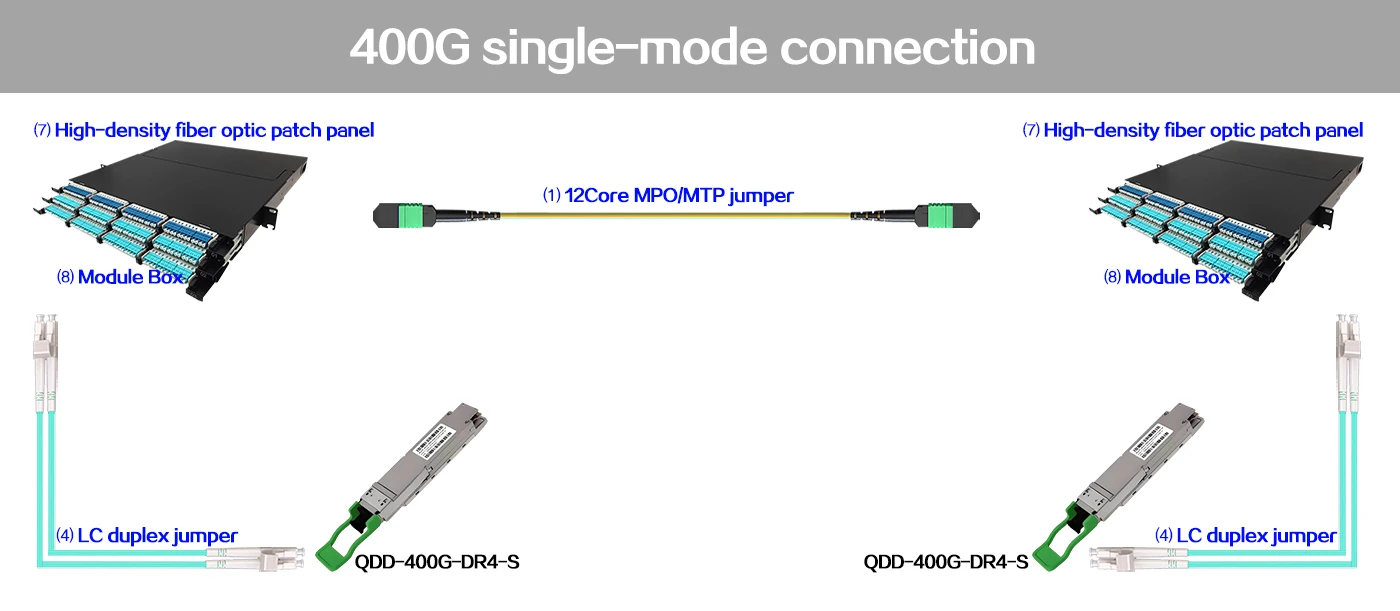

MTP Cable 400G-400G direct connection mode

When the 400G QSFP-DD DR4 optical modules at both ends of the machine room can be connected through MPO/MTP-8 single-mode fiber jumpers to achieve 400G transmission.

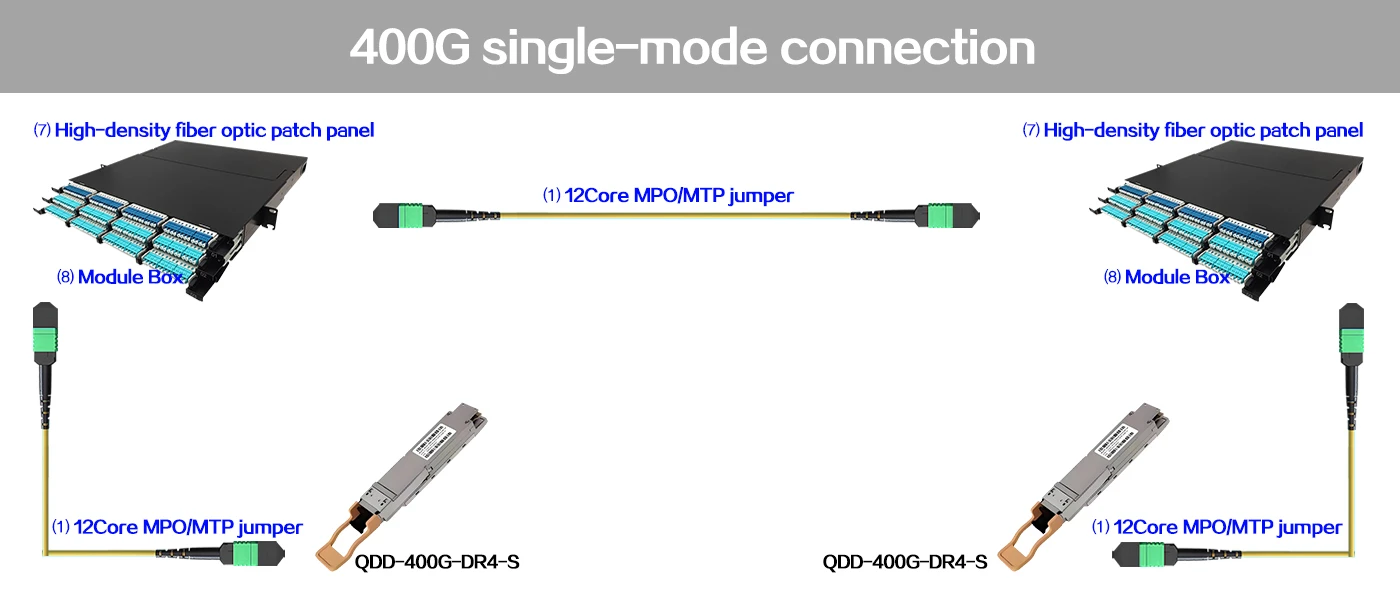

MTP Cable single-mode connection

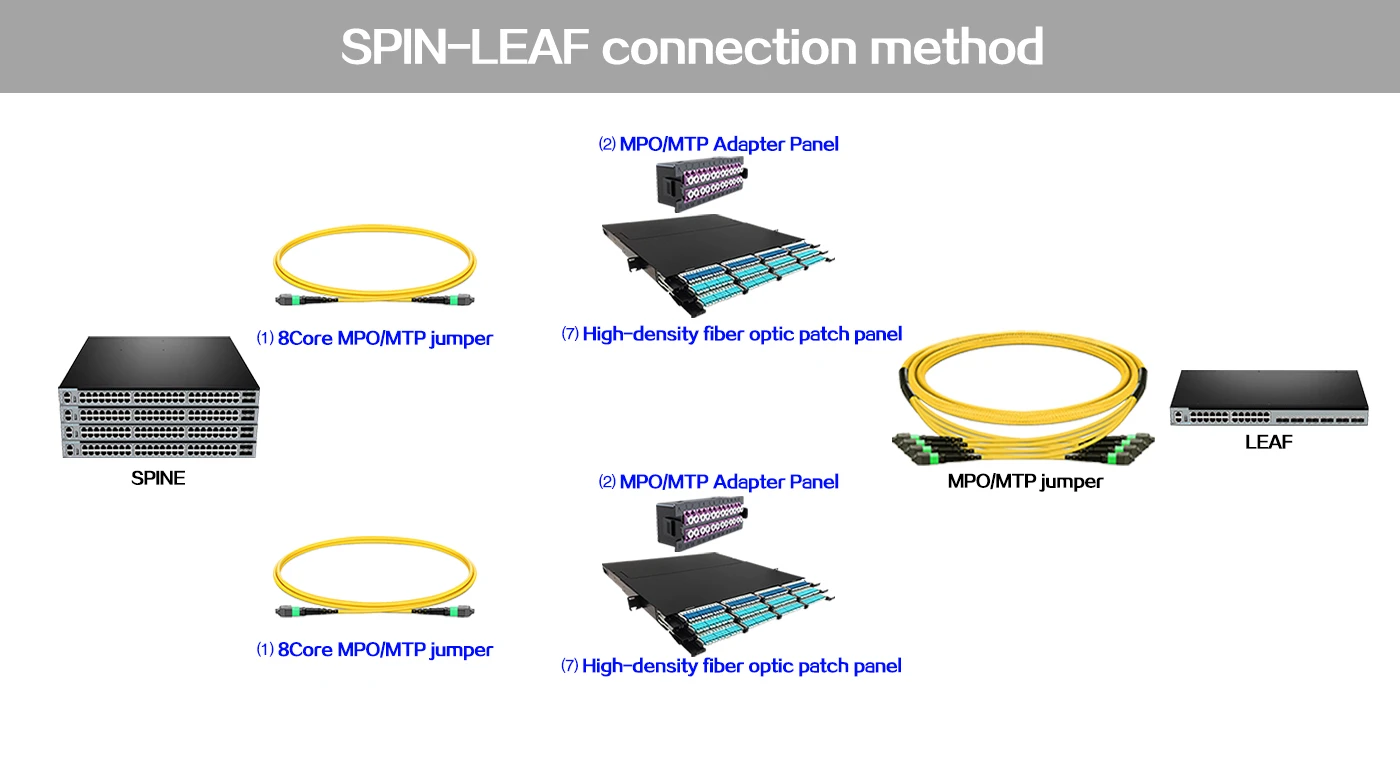

MTP Cable SPIN-LEAF connection method

MTP Cable Application

High-speed interconnection in data centers

It is used for direct connection of 40G/100G optical modules, supports 400G high-speed transmission, and can improve wiring density and transmission efficiency. For example, 400G QSFP-DD DR4 optical modules can be directly connected through MPO/MTP-8 single-mode fiber jumpers.

High-density wiring scenarios

In the backbone wiring of data centers, MTP/MPO trunk fiber jumpers are used in conjunction with adapter modules to achieve interconnection and cross-connection between devices, saving 45% of wiring space. Branch jumpers are used to connect devices with different rates (such as 10G and 40/100G devices).

100G/400G transmission expansion

Supports branch connection of 100G QSFP28 optical modules to 4 25G SFP28 optical modules, or interconnection of 100G CFP optical modules to another CFP.

Fiber-to-Building Applications

It is used for fiber-to-the-building (FTTB) wiring to meet the needs of high-density fiber access.

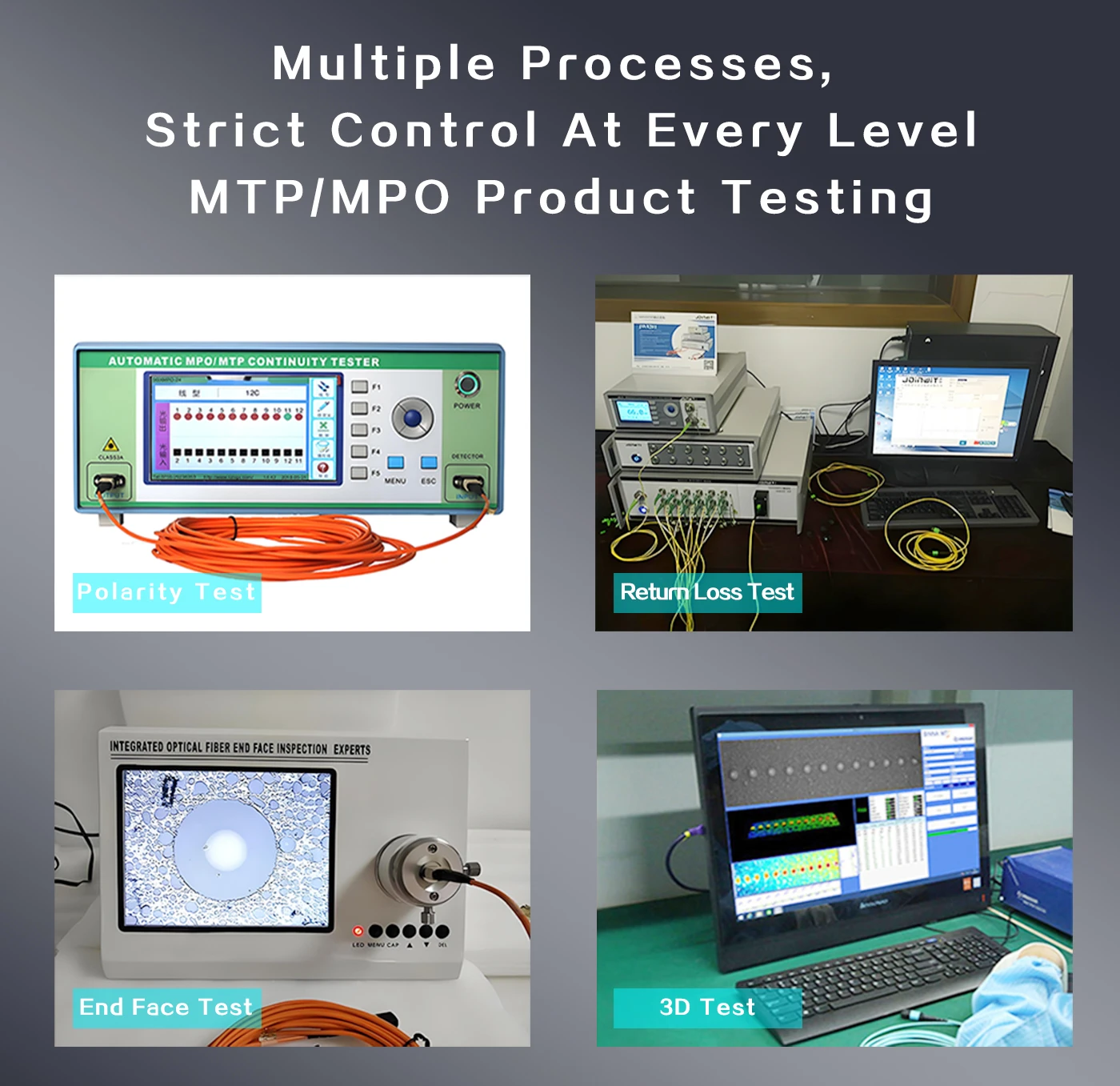

MTP Cable Test Series

MTP Cable Polarity Test Process

End face cleaning: Use special equipment to remove end face contaminants to avoid affecting the test accuracy.

Morphology detection: Analyze the end face microstructure through 3D imaging technology to detect surface roughness, scratches and other defects.

Insertion loss test: Measure the contact loss between the fiber end face and the connector ferrule to evaluate the signal transmission quality.

Polarity verification: Confirm the correspondence between the number of fiber cores and the connector guide hole to prevent communication failure caused by wrong connection.

MTP Cable Test Key Indicators

Cleaning efficiency: It must reach more than 98% to ensure that there are no residual stains on the end face.

Detection accuracy: The resolution of 3D morphology detection must be less than 1.5μ, and the insertion loss error must be controlled within 0.3dB.

Test time: It takes about 10 seconds to detect a single fiber core of a 12-core MPO jumper, and the overall test takes about 2 minutes.

MTP Cable Test Common Problems

Pollution sensitivity: Tiny particles on the end face will cause increased loss, and non-contact cleaning methods are required to protect the end face.

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.